Custom Magnetics & Assemblies

Custom products are the special focus of BH Electronics. For each application, be it small or large, our engineers draw on extensive resources and experience to create exactly the right product for each application. Once designed each product is constructed as a prototype to verify the design and provide our customer with an example of the finished item for testing in their facility. These prototypes are prepared in our complete prototype facilities which include special machining, molding and assembly processes as well as extensive testing equipment. Examples of typical product developed in this way are shown below.

Ultra-miniature Composite Video Balun

When the video surveillance industry began changing from coaxial to UTP (Unshielded Twisted Pair) cables for device interconnection, there was a great need to support legacy equipment such as cameras, video switches, distribution hubs and monitors with Category 5 UTP. BH Electronics responded to this need by developing and manufacturing the L40-0212. Our video balun is a catalog standard balun PC board assembly that is interchangeable between brands by employing unique plastic cases for each customer. The L40-0212 is an ultra-miniature design that allows it to easily fit in crowded rack mounted panels.

Frequency Domain Multiplex Filter

Digital Subscriber Line (DSL) services available from local telephone companies often require that existing telephone wiring be “multiplexed” to permit telephone and high speed data traffic to share the same wire pair. This requires the development of low cost, high volume passive filter circuits that separate the signals by frequency. This low-pass filter presents insignificant resistance to signals between DC and 4KHz, but blocks signals from 25KHz to 1.1 MHz. Our low-pass, high-pass and band-pass filters are available for both signal and power applications. Unit volumes from a few parts per month, to many thousand per week are supported.

Low Profile Transformer

The laws of physics require that a transformer be of a certain minimum size to properly function. This size is often in conflict with the space available on a PC board. Our design team worked together with our customer’s engineers to create a Low Profile Transformer. The particular application that led to its creation required a transformer design that was too tall for the assembly into which it was to be placed. Board space was not available to permit a larger footprint. The solution was a part that can be mounted upside down with the magnetic core protruding through a hole in the PC board, thus meeting the overall assembly height requirements.

CATV Balun

Category 5 & 6 unshielded twisted pair cable has steadily become the standard medium for commercial and institutional distribution of Ethernet signals in local area networks. The ready availability of this cable made it a popular choice for delivering several different signals through it, including challenging cable television signals. BH Electronics patented a balun with a 5MHz to 860MHz bandwidth to accommodate the cable signals. The product won the prestigious R&D Magazine 100 Award for being one of the 100 most significant inventions of the year, and was incorporated into Lynx Broadband TV signal distribution products.

High Operating Temperature Magnetics

In order to provide power conversion, power control and communications to the sophisticated, high operating temperature bits used in oil well drills, we have developed inductors and transformers that are designed to operate continuously at temperatures up to 250°C. The pictured components fit inside the drill casing and perform reliably at temperatures of 220°C, providing necessary small diameter packaging and support of power levels up to 100 Watts.

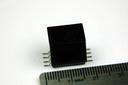

Planar Transformer

The pictured high reliability planar device replaced a low profile wire wound transformer in a high vibration environment. This Planar Transformer was built using multilayer printed circuit board technology. At its heart, this transformer is comprised of an 18 layer printed circuit board with windings etched onto the layers and plated through holes to provide interconnection between layers. This efficient construction technology maximizes space utilization while providing the highest levels of performance and repeatability from part to part, all while withstanding shock, vibration and temperature extremes.

Precision Tuned Filter Assembly

We developed this precision bandpass filter in three versions to pass frequencies of 250KHz, 500KHz and 2MHz. In each case the tolerance on the passband frequency was only ±0.4%. This tight tolerance required that each part be individually tuned to meet the demanding specification.

Ultra-low Capacitance Transformer

Our customers often provide us with difficult specifications for their custom orders. The Ultralow Capacitance Transformer was one of our most challenging designs, requiring a low level of interwinding capacitance, an extremely low level of noise coupling, high voltage isolation, low physical profile and operation from 200Hz to 6.5KHz. Our designers opted for a dual bobbin transformer, creating an efficient and dependable transformer in the smallest possible size.

Intrinsically Safe Transformer

To create this intrinsically safe transformer with a 6mm minimum distance between its primary and secondary metallic elements, we folded the spacing to maximize the creepage and clearance mandated by safety agencies while keeping the package size as small as possible. The transformer in the image is only 12 x 14 x 12mm. BH Electronics has created several designs that use this technology, mostly for medical applications that require transformer isolation of small electronic devices that are directly connected to patients.